The purpose of this page is to compile a list of information that could be useful and helpful when towing or loading a trailer. There are a number of variables that lead to safely towing a trailer and can’t be written into a few simple rules. The information listed here has been compiled from our knowledge and other sources. It is important to know how to accurately load a trailer so that it can be safely towed at reasonable speeds.

The following are some of the problems you may encounter and some basic rules that you need to know. It is up to you to decide what will work, and add the common sense it takes to safely tow a trailer. If a trailer doesn’t tow properly when all the basic rules have been followed, the answer can be very complex, because the result can be an oscillating trailer. This is usually caused by a trailer that is “tail heavy”, and adding more tongue weight will cure the problem. If it doesn’t, you need expert help. The moment a rig shows any tendency in this direction you should slow down and get some expert help right away. Oscillations are very complex because they can be the result of several components working in unison. Speed and wind are two of these components, so you should never drive faster to try and eliminate the oscillation or any other problem. You should start off by towing the trailer without any load. If a problem such as this exists, go to your hitch shop or the dealer that sold the trailer. The information covered here cannot solve problems such as these if the basic rules have been followed and oscillation still occurs. It can be very dangerous to experiment with an ill handling rig, especially on a public road.

If you haven’t already purchased a tow vehicle you can customize its specifications to your towing needs. Most likely, however, you already have the vehicle you will be using to tow, and have based your trailer purchase on its capabilities. It might be wise to ask yourself at this point if the tow vehicle is really big enough to have the brakes and suspension it takes to safely tow your trailer. There isn’t any good way to overcome a problem such as this, short of trading up to a vehicle with more capacity. If the suspension isn’t heavy enough, the brakes probably leave something to be desired. You can get this type of information from manufactures of trailers, trucks, and automobiles but they tend to be optimistic, quoting maximum capacities rather than recommended capacities. Remember also that a half-ton pickup may be able to carry 1000 pounds of weight in the bed, but probably cannot support 1000 pounds at the hitch without special modifications to the suspension. So if you hook up your twenty-four foot cargo trailer to your nice, new half-ton pickup and the headlights are aimed at birds roosting in the trees, there should be a clear message that something is wrong.

You can’t always correct the problem by moving the load if the tow vehicle isn’t capable of handling the required hitch weight. Moving the load back in the trailer could make for a very unstable and dangerous condition, and leaving too much weight on the hitch can also cause a dangerous situation where the tow vehicle doesn’t have enough weight on the front wheels to control your rig. When you hit the brakes, the trailer dives lifting the front end even more, and you lose most of your braking and steering at the same time. Several types of weight re-distribution hitches are available (contact our parts department for additional information) that can dramatically help your handling by spreading the forces to both axles, but they cannot compensate for inadequate towing capacity or overloading.

(LEFT) Trailer “Dive” during heavy braking increases the effect of tongue weight.

(RIGHT) Weight distributing hitch transfers loads to frame and to both axles of tow vehicle for safer stops and smoother ride.

Talk to the service department about your particular needs. This leads to the first and most basic rule of trailer towing:

“The tow vehicle and hitch must be capable of safely handling at least 15% of the gross weight of the trailer (total weight of trailer plus contents). Fifth wheel trailers usually have up to 25% of the gross weight on the hitch.”

Although it is beyond the scope of these instructions to cover everything, it is important to mention brakes. If you can’t get to the top of a hill from lack of power you can usually pull over and it may cause an inconvenience but not a disaster. If the brakes fail going down a hill you have a problem that can cause a disaster. You can’t have too much brake. Disk brakes are better than drum brakes. Four electric brakes on your trailer are better than two. New pads are better than old pads. You should be able to stop your rig on a hill without the trailer brakes. If you can’t, you’d better pay a lot more attention to that corroded connector you have been hooking up your trailer with.

When learning, get on a lonely road without any traffic and try practicing panic stops. Of course, you shouldn’t just slam on your brakes. You should try to slowly shorten your stopping distance by applying more pressure. Don’t take it to the point that you lose control, just enough to get a feeling of what it takes to make a quick stop and the distances involved. As a result of this exercise you will find yourself leaving more room in front of your vehicle. Don’t ride the brakes going down hills as this overheats brakes, causing them to lose effectiveness. Use the engine and lower gears to control the downhill speed on long hills. Learn how electric brakes work and how to adjust the modern day controllers that actuate them. Remember that the slightest pressure to the brake pedal will apply the electric brakes. Keep your foot off the brake pedal unless you intend to use them. They shouldn’t be allowed to be on for extended periods. The basic drag of these brakes are set with the control, not how hard you press the pedal. A pendulum type control will electronically add more brake as you stop, but if you have your controller turned all the way up, the slightest pressure on the pedal could lock your trailer brakes.

Before towing anything, have your hitch inspected by a qualified hitch installation company, and have them determine what the maximum tongue weight can be. This is usually 10% of the hitch’s rated capacity. Note, the correct term is hitch, not ball. A ball is rated by its own towing capacity. A hitch is rated by not only its towing capacity but also by the tongue weight. Again, the safest way to accomplish this is to take your vehicle to a shop that specializes in installing hitches. If you have a bumper type hitch, don’t tow anything that can’t easily be lifted onto the ball. The biggest error you can make is “cheaping out” and not going to a qualified shop.

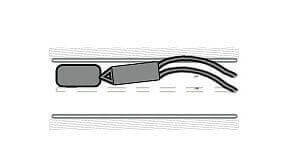

All your lights must work to be legal and safe. The weakest link is the connector. They corrode easily and need constant attention to keep the system working. (Be careful when cleaning connectors so as not to short them out.) The wiring to the connector should be carefully routed so that it can’t come apart in tight turns or chafe through and short out. Remember, electric brakes also run through this connector. Have an observer confirm your brake lights, turn signals, and running lights are working properly each time you hook up.

TIRES – Tires have to be checked frequently with a trailer because a flat can go unnoticed on multiple axle trailers while it’s being towed. Running with a flat can cause it to catch fire and burn up your rig. With multiple axles or tandem wheels it’s hard sometimes to see a flat tire as the other tires are supporting the weight of the rig and the flat spot is less noticeable. A quick check can be made by “thumping” each tire with a tire iron or rod to make sure they all sound the same. Each time you gas up, walk around the trailer and give a quick check by feeling each tire with your hand. A tire that is getting low will be hotter than the rest. There is no substitute, however, for actually measuring tire pressures to make sure they are all within safe limits. This should definitely be done before each trip.

NOTE: The most common causes of tire failure are overloading and under inflation. Both result in excess flexing of the sidewall which causes heat buildup, excessive uneven wear, and eventual failure. Continuing to run with a flat can cause it to catch fire.

WHEELS AND LUG NUTS – Trailers have higher wheel loading than passenger cars or trucks. Tandem axles do not steer, and wheels are subjected to high twisting side loads in tight, slow turns. This causes the wheel to flex which tends to loosen wheel lug nuts over time. Always check lug nut torque before each trip. A suitable torque wrench only costs about $30 and is a worthwhile investment considering the value of your trailer. Aluminum wheels are more likely to have the lug nuts loosen then steel wheels, especially after the initial installation.

Wheel lug nut torque is usually much higher than that specified for passenger car wheels. Check your particular trailer’s recommended specifications. Most are in the 90-95 ft.-lb. range. On a new trailer, check the torque on all wheels after the first 25-50 miles of towing. Also recheck any wheel that has been removed and replaced after towing 25 to 50 miles. Do not drive a loaded trailer with a missing lug nut or damaged lug bolt.

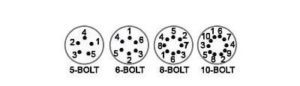

Torquing order for various wheel lug nut patterns as suggested by a trailer manufacturer in their owner’s manual.

Wheel lug nuts are usually torqued in a “star pattern” pattern for 5- and 10-bolt wheels, crossing over to opposite sides as you work around the wheel. A “cross” pattern is used for 4-, 6- and 8-bolt wheels. Shown above are some suggested orders for tightening nuts on various bolt patterns. Using the numbers on the above diagram, a popular alternative for the 5-bolt pattern would be a 1-2-5-4-3 “star pattern”.

WHEEL BEARINGS – Axle wheel bearings also occasionally need attention. Feel with your hand at the hub to check for one that may be running hotter than the rest. (Be careful. If the bearing is adjusted too tight or is running without grease as it can get VERY hot!) A hot bearing needs immediate attention. Most often either more grease or proper adjustment will ease the problem, but replacement may be necessary. Boat trailers are a particular source of wheel bearing problems as they are often put in and out of the water. A warm bearing that is suddenly cooled by being immersed in water tends to suck water into the inside as the air cools and shrinks. The water causes the bearings to rust and fail.

It would be overly simplistic to say, “put the heavy items over the axles”. Sometimes a lot of little items can far outweigh one big one. Don’t put big, heavy items in a place where they can’t be securely tied down. A glued down rug makes a great floor for a cargo trailer because things tend to stay put and don’t slide around. Of course, it would be easy to say everything should be securely tied down but it would also be unrealistic. Start with top-heavy items if you have them. That’s usually a good place to start because you must have plenty of room available to properly tie them down. Tying them straight down is not secure enough. They need to be tied off at several angles or they could fall over in an abrupt change in speed or direction. You need room to accomplish this. Smaller items can be used to fill the spaces around them later. The Parts department carries a large selection of tie down straps and securing devices to assist with these tasks.

Once you have the heavy items located, check the tongue weight with a scale. If the load is radically off, make the changes necessary to get close. The smaller items can be loaded in such a way that they balance out the load. They should be located so they will stay put. Placing them next to items that have already been tied down helps, but your main concern should be to not lose the balance of the trailer. Don’t forget you can also get one side of a trailer a lot heavier than the other without a little planning. This can cause a very serious problem when cornering, even causing the trailer to turn over in a sudden turn.

Top heavy loads can cause problems not only in cornering but also in hard braking. They have a tendency to make the trailer “dive” in hard braking conditions. This suddenly increases tongue weight and can decrease front axle loading just when you need steering and those big front disc brakes the most. Center top heavy items or arrange the remainder of the load to act as a counter weight to minimize this effect.

Top heavy loads can cause trailer “dive” under hard braking, possibly reducing steering and braking control.

Never place heavy objects on add-on devices hung on the rear bumper or placed across the tongue frame. A bicycle may be fine to hang out in back, but not a motorcycle. This places heavy objects where they will dramatically affect handling in corners or bumps. Heavy weights placed well behind the axle can also aggravate swaying in turns.

It is not possible to cover every conceivable loading or trailering situation. The best advice is to use good common sense and to always allow plenty of margin for safety. The purpose behind this text is to try to give you the necessary information to make intelligent, informed decisions when loading. The ultimate responsibility for using that information correctly lies with you and you alone.

Your trailer’s springs, axles, tires, and chassis were all designed to handle a certain maximum load. This load consists of the empty trailer itself, plus the added weight of cargo that you add. This is called the Gross Vehicle Weight Rating or GVWR. In addition, each axle has a maximum weight that it was designed to support. This is called the Gross Axle Weight Rating or GAWR. The total of all axle loads plus the tongue weight should not exceed the GVWR.

Remember: The GVWR is only as much as the weakest link. Look at your tire ratings as they tend to be the weakest link. Add up all the tire capacities to determine the total GVWR for the trailer.

CARGO CAPACITY = GVWR – Empty Trailer Weight

Overloading a trailer beyond its rated capacity, even though it may be well balanced and seems to handle fine, is a very dangerous practice. Eventually something is bound to fail with dramatic and unpleasant results. Overloading places excess strain, not only on your tow vehicle causing possible failures at the hitch or in your capacity to safely bring it to a stop in an emergency, it also overloads the trailer’s frame, axles, bearings, and tires.

Be leery of home-made trailers. It is amazing how many bad ideas can be incorporated into this group. Do you really want to risk lives, your own included, to save a few bucks on a trailer? How many trailers have you seen fishtailing down the road that were manufactured by a credible company? Probably not many. If you now own an ill-handling, no-name misfit, either get it fixed by a professional or get rid of it by junking it. It’s unethical to sell or use a trailer that could cause a serious accident. Good cargo trailers are usually designed to maintain a proper tongue weight if they are loaded evenly.

It is up to you to find out what the maximum gross weight of your trailer should be. Trailers made by reputable manufacturers should contain a tag or instructions which list loading limits. This can be more of a problem if you have a trailer built twenty years ago by a company that no longer exists and the tag or instructions are missing. If you cannot obtain actual figures from the original manufacturer, take it to a reputable trailer sales or repair facility and get an expert to give his best estimate of its capacity.

Load your trailer well below the maximum for the first tow with a new rig or while you are learning. Keep track of the weights of the individual items as you load them. When in doubt, guess high. Using a scale, adjust the load so that you have around 12% to 15% of your best estimated total weight on the hitch. Attach the trailer to the tow vehicle and note how much the rear end drops. (If it looks excessive, check the tow vehicle’s load capabilities again.)

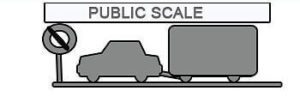

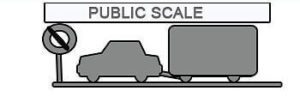

Though it is not necessary to weigh your trailer every time you load it, it is a good idea in the beginning to have a good cross-check to your estimates. Once you have a feel for it, a good estimate is usually close enough unless you are loading to near your trailer’s maximum limits. A 1000-pound error in total weight is only a 150 pound (15%) error in tongue weight.

Weigh the trailer by having just the trailer wheels on the scale. You do not need to disconnect it from the vehicle. Add this weight to the weight at the tongue that is attained with a scale and you have your gross trailer weight. Knowing the total weight and the tongue weight allows you to calculate the percentage of weight on the hitch. While you’re there the first time, it would be a good idea to also check the vehicle weight at each axle to make sure it’s not loaded beyond the manufacturer’s specifications.

Towing a trailer has a responsibility similar to properly driving your car. You wouldn’t think of letting your children drive on the road without the proper training, and you shouldn’t take a fully loaded trailer that could be improperly loaded onto a busy road to learn with. It is a skill that has to be developed and a responsibility that shouldn’t be taken lightly. If you’re towing a travel trailer for the first time, you have to start learning with a full load. Drive only when traffic is light and don’t drive where traffic conditions might force you into driving faster than you are comfortable with. Get a friend with this type of experience to help you learn. Don’t be embarrassed to ask questions or park when it’s windy. Learn what it takes to keep from ruining your transmission when pulling heavy loads up a hill or burning your brakes up going down the other side. It is a skill that you can take pride in. The hardest skill to learn is to know when not to tow a trailer.

Travel trailers, boat trailers, and specialty trailers are usually designed to have the proper hitch weight, but it would be intelligent to check them. Make sure your hitch is capable of handling the load. You can still screw up the design by putting something heavy where it was never intended to go such as a heavy outboard on the back of a sailboat. Another way of getting in trouble with a boat is towing it when it has a lot of water in the bilge from a rainstorm. If you add heavy items to this type of trailer, put the extra weight over the axles. If you’re putting a boat on a trailer for the first time, use a scale to find the proper place to locate the boat and adjust the trailer to fit the boat.

Wind can create havoc when towing a trailer, causing oscillations or sudden pulling to one side. Thirty mile an hour crosswinds can blow you off the road if there is a sudden gust. For example, say a hard gust of wind hits your rig from the left. Your rig pitches to the right and moves towards right. In order to stay on the road you turn left. With the rig leaning to the right, the centrifugal force generated by the left turn can be the added ingredient that puts you on your side, or worse yet, down the side of a ravine. The only way to help lower the risk traveling in these conditions is to slow down. This eliminates the centrifugal force that happens when you correct, and if the wind did blow you over it wouldn’t be such a violent crash. The safest way is not to drive in extremely windy conditions. That’s what the professional haulers do, and so should you. Park it until it’s safe to continue. Wind can also have a dramatic effect on your fuel mileage when towing a heavy load. Plan your fuel stops accordingly.

NOTE: Several types of trailer sway control braces are available that can minimize the effects of wind gusts and passing trucks.

Wind From Passing Trucks – An interesting thing happens when being passed by faster-moving buses or large trucks. Large vehicles develop a high pressure wave of air in front of them and low pressure area to their rear as they go down the highway. This is variable and is dependent on the shape of the truck and the existing wind conditions. The effect is such that as the truck comes up to pass on your left, first your trailer and then your tow vehicle will be pushed to your right by the truck’s “bow wave”. As the truck passes, the low pressure zone will then pull you back to the left. You must steer first left and then right to counter the effect. It’s not particularly dangerous, but it does keep you on your toes.

HANDLING TRAILER SWAY – If swaying occurs, steer as little as possible while you slow down. Because of your natural lag in reaction time, quick steering movements will actually make things worse and cause the oscillation to increase. Application of the trailer brake usually tends to help keep the vehicles aligned, while heavy braking with the tow vehicle may reduce trailer stability. Until the problem is identified and solved, travel at reduced speeds.

Heavy items loaded to one side of the trailer can cause oscillation or handling problems in turns.

NOTE ABOUT LOAD EQUALIZING HITCHES…

A load equalizing hitch is selected based on the trailer’s actual tongue weight rather than on gross weight. This type of hitch has some real advantages, but government studies have shown they can actually work too well, lightening the load on the rear wheels of the tow vehicle and reduce traction. This kind of hitch should be selected carefully, installed by professionals and its operation understood by the user. This type of hitch is HIGHLY recommended.

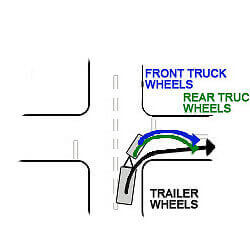

WATCH YOUR TRAILER’S WHEELS IN TURNS…

The longer the trailer, the wider you must swing in a turn to make sure the trailer wheels clear the inside curb.

SOMETHING TO THINK ABOUT…

A temporary increase in loading occurs during dips or bumps in the road. A severe dip causes increased weight to suddenly be placed on hitch, axles, and tires. Though hitch manufacturers take this into consideration in their designs, an overloaded or old, cracked and rusted hitch or tongue can be suddenly stressed beyond capacity, causing it to fail. Watch for bumps and large dips in the road and try to slow down for them. A conservative safety margin in loading will also be helpful in this type of unforeseen circumstance.

NOTE: Whenever the trailer is detached from the tow vehicle, block the wheels so it is impossible for the trailer to roll off on its own. Better yet, don’t ever detach the trailer on any grade.

4125 Palisades Place Armstrong, BC, Canada, V0E 1B6

Call:

Toll Free

HOURS OF OPERATION

Mon - Fri:

8:00am - 5:00pm

Saturday:

9:00am - 3:00pm

Sunday:

Closed

© 2024 BC Cargo Trailers. All Rights Reserved